午前中色々やったが、状況変わらず、、ログイン画面状態でも落ちるので今はこうなっている。

そろそろあきらめることにした。良い部品は取り外して他のPCに引っ越しさせよう。

2018 年 10 月 のアーカイブ

今日のWIndows 10 機状況

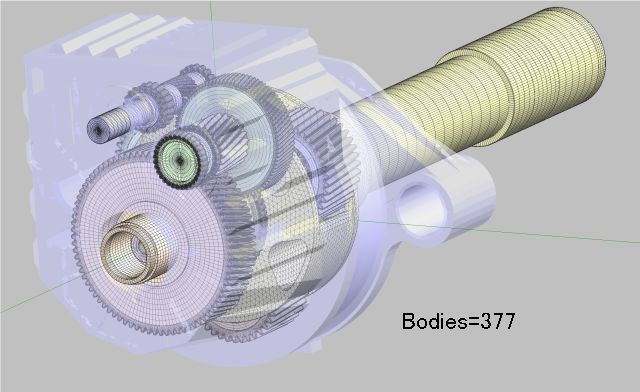

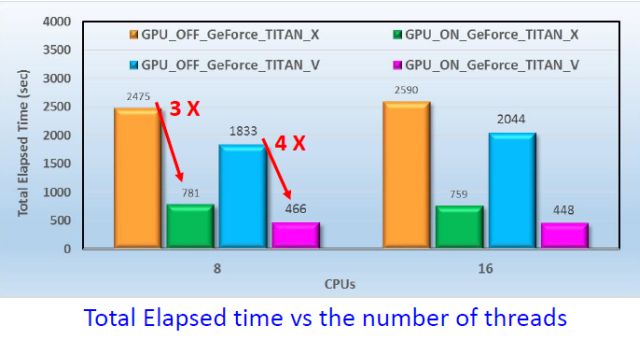

2018 年 10 月 25 日 木曜日ANSOL T3D GPU性能テスト

2018 年 10 月 25 日 木曜日ANSOL T3D Rev344 GPU性能テスト結果です。

テストモデルは、ウインドタービンモデルサンプルデータ。

今回は、今回借用した Titan V と自社所有のTitan X との比較も行います。

Titan V と X、名前は似てますが性能は随分と違うようです。

ANSOL T3D GPU計算で効果があるのは、倍精度演算性能=FP64(数値が大きい方が高速)です。

搭載OS : Windows10

搭載CPU: Titan XがXeon E5-2687w, VがXeon Platinum 8170

スレッド数 8, 16 でGPU使用有無の場合の結果です。GPU機能は現状ベータ版ですが効果大。

今日のWindows10 デスクトップ機

2018 年 10 月 24 日 水曜日ANSYS 19.2 GPU性能テスト

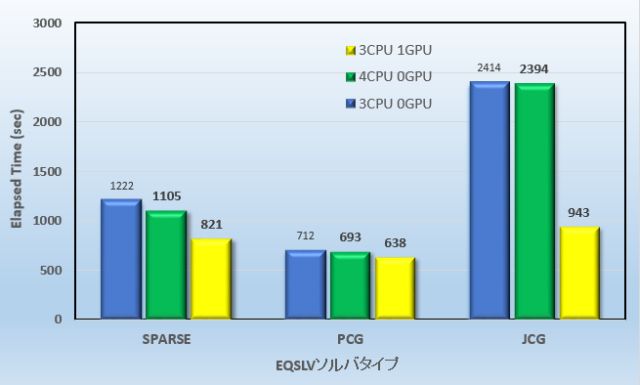

2018 年 10 月 24 日 水曜日現在借用中の、Xeon Platinum 8170 + NVIDIA TITAN V 機でANSYS 19.2線形解析のテストを行いました。

以前のANSYS Mechanical APDLでGPUオプションを使用するには、別途ライセンスが必要でしたが、

最近では、CPU数を1個減らせば、代わりにGPUを1個使えるように変更(改良?)されたようです。

手持ちのライセンスはAPDL標準、使用できる最大CPU数は4までなので、

(1) SMP 4CPU, GPUなし

(2) SMP 3CPU, GPUなし

(3) SMP 3CPU, GPU使用

の3ケースをGPUオプション使用可能な3タイプのソルバについて試してみました。

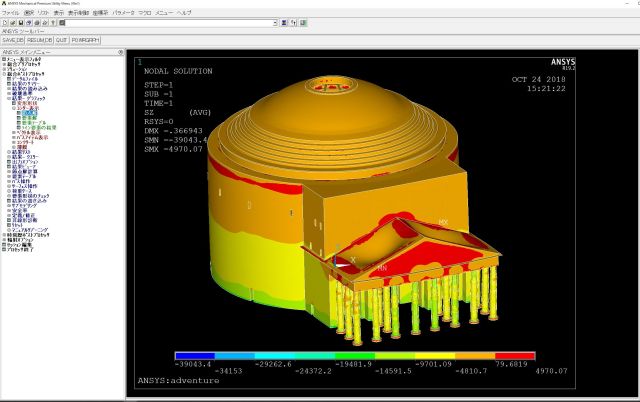

テスト問題 - Adventure Projectが公開しているパンテオンデータをANSYS用に変換して使用

2M Nodes, .3M Tetra10, Linear Static Analysis.

注意)ANSYSは、”認定されていないGPU" "ANSYSより新しいGPU” を使っている場合、

「このGPUは対応していません」

これを避けるには、環境変数 ANSGPU_OVERRIDE=1 を設定しておく必要があります。

測定結果 - 全てのソルバタイプにおいて、4CPUよりも 3CPU+1GPU(黄色)の方が高速

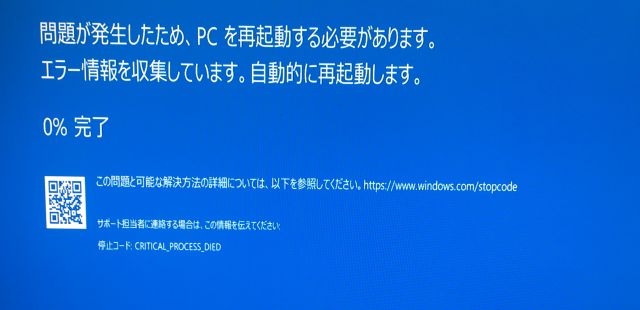

Windows10 デスクトップ機 不調 ”CRITICAL PROCESS DIED”

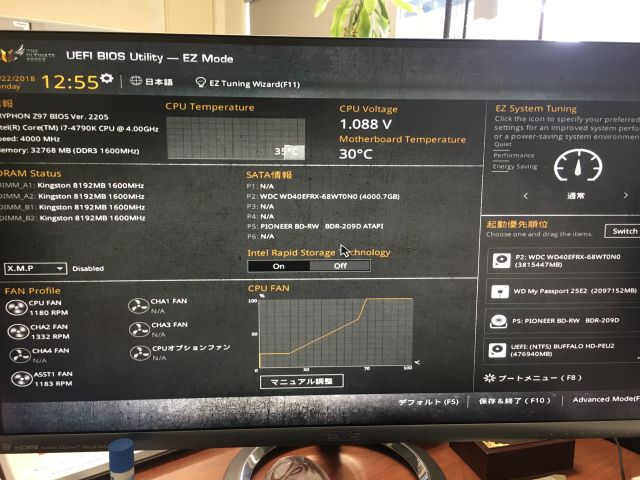

2018 年 10 月 22 日 月曜日土日と会社に来なかった。今朝出社してデスクトップ機モニタをオンにしたらBIOS設定

画面になっている。何故か? BIOS設定画面を終わるが再びこの画面に戻ってしまう。

無理やり電源を入れ直すと普通に起動するのだが、一定時間(規則的ではない)経過すると

この画面になって落ちる。放置しておくとBIOS画面になってしまう。

ネット上で色々調べたが、修復方法の決定打はなさそうだ。

このマシンは、2015年9月に Windows7で購入、Windows10無償アップグレード期間中、

勝手にWindows10になってしまったマシンだ。

OSの回復とか復元とかでは無理そうだ、、、、捨てるには未だ早すぎる、、、どうするか?

2018MotoGP第16戦日本GP@もてぎ (2018/10/21)

2018 年 10 月 22 日 月曜日土曜は夜まで都内 学士会館~神田で同窓会、そして日曜は朝からツインリンクもてぎです。

モトGP日本グランプリ、入場者数過去最高とのことで、どこも人で一杯。

場内その1

各メーカのブース

モトGPは海外からの観客が多い。自分の場所はV2スタンド。前列は台湾?からの若者達

左側はイギリスから来たクラッチローファン、後ろの方々はヨーロッパから。

百里基地からはF4EJファントムも登場、飛行中のファントを間近でみるのは小学生の頃、

野辺地町の山中で、三沢基地から飛び立ったファントムに追いかけられて? 以来かな。

平成30年 東京鏡ヶ丘同窓会@学士会館

2018 年 10 月 22 日 月曜日2018/10/20(土)昨年は参加できなかったこの集まり、今年は参加できました

今回もS25年~H30年卒までと、来賓含めて140名の参加者で盛り上がり。

アトラクション - スコップ三味線 師範登場

ところで、今回の参加者に私と同じ苗字の方が3名。お互いに話してみた結果、

- お寺は3名とも弘前市内の同じお寺

- お墓の場所も、お寺入口から入って左、、、、要するにすぐ近く。

自分の墓の周りは同姓が多いとは思っていたが、まさかの結論。遠い親戚に違いない。

LSDYNA Xeon Platinum 8170(26Core x2CPU ) 試用結果

2018 年 10 月 22 日 月曜日ANSOL T3D GPU版性能測定のため、トーワ電機様(UNIV)の貸出機を利用することができました。

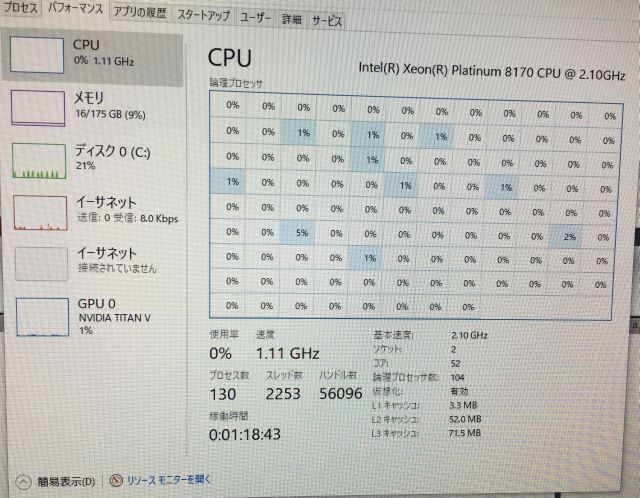

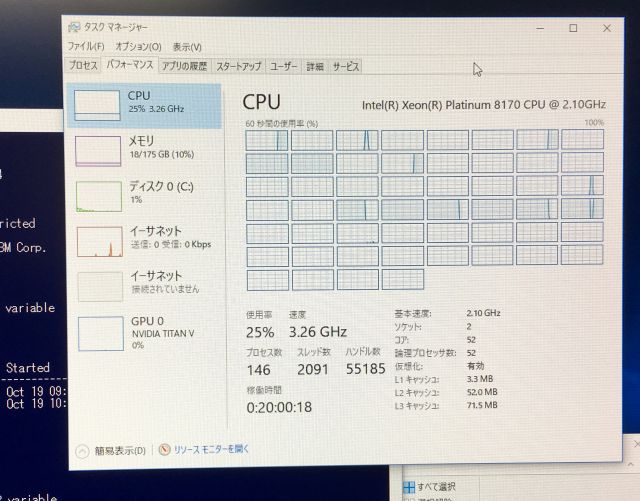

スペック Xeon Platinum 8170 (26Corex2CPU), RAM 176GB, WIndows10

GPU NVIDIA TITAN V (12GB)

筐体は、これまでと同じ。

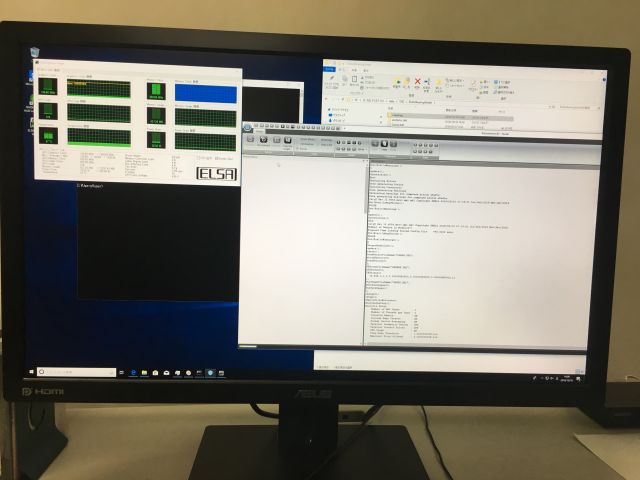

Windows 10、ANSOL インストール中

ハイパースレッドON で届いたので、104スレッドのタスクマネージャ。

グラフではなく、数値で表示!! 初めて見た画面、

性能測定時のためにハイパースレッドをOFFにしたら見慣れたグラフ表示になりました。

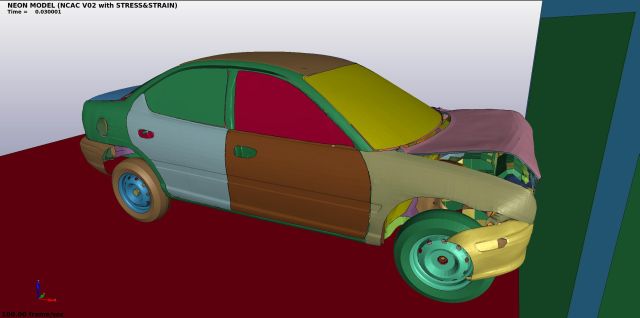

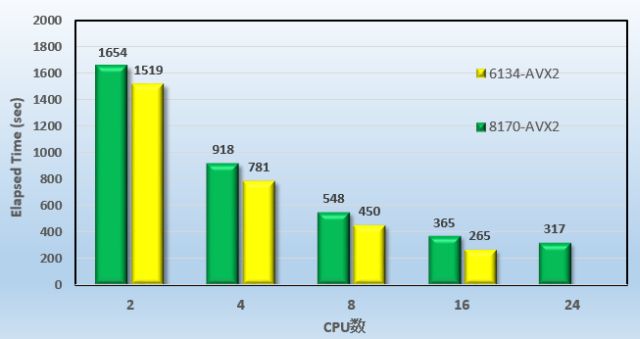

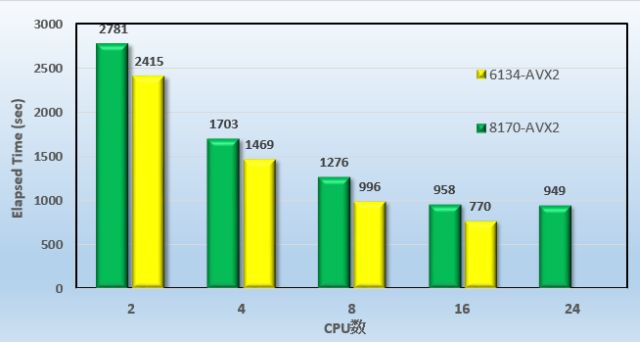

ANSOLテスト前にLSDYNA R10.1 でCPU性能測定。使用データはいつものNeon_Refined

比較対象は、Xeon Gold 6134

6134 - 8Core x 2CPU, 3.2GHz/TurboBoost 3.7GHz (CentOS7.5)

8170 - 26Core x 2CPU, 2.1GHz/TurboBoost 3.7GHz (Windows10)

ベースクロックは6134が速いので、結果もそうだろうと思ったが、性能差はクロック比程ではなかった(かな?)。

MPP版、SMP版ともにライセンスの都合で最大24コアまでの結果となっています。

MPP 単精度版

SMP 単精度版も測定してみました。16以上CPU数を増やしても効果はなさそうです。

Xeon

LSDYNA 新機能紹介セミナ 2018

2018 年 10 月 16 日 火曜日今年も講師にLSTC社 開発担当Dr. Isheng Yehを招待、ユーザ向けセミナを実施しました。

今回は、都内で合流。タクシーに乗ったらTOKYO 2020仕様、自分達には珍しかったので

ドライバさんに記念写真を撮ってもらいました。

先ずは再会の乾杯

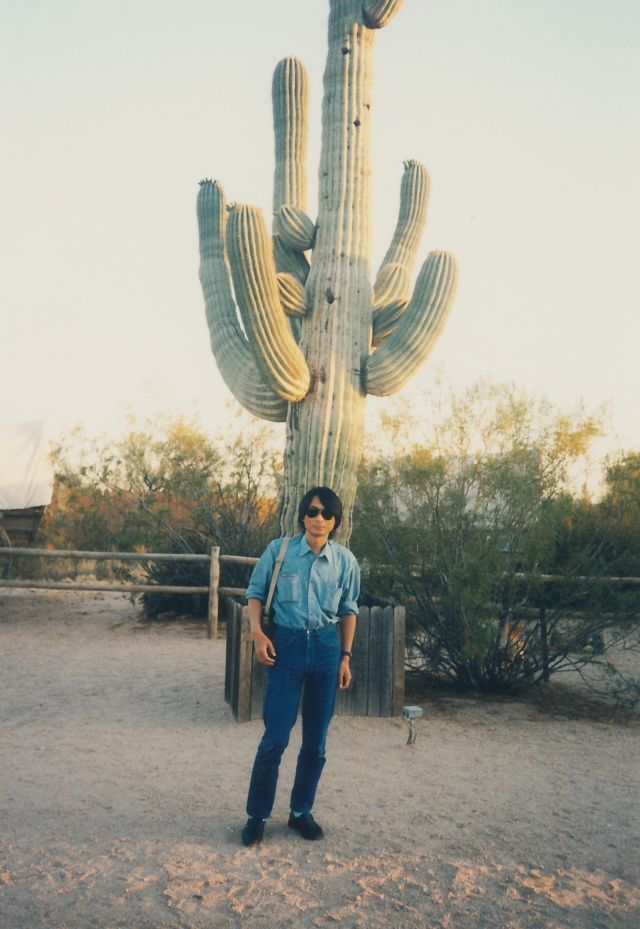

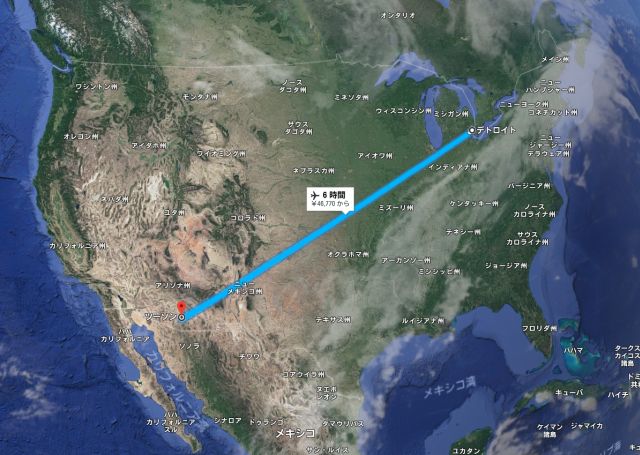

イシェンとは、6月のデトロイト以来だ。その後彼はデトロイトからアリゾナに引っ越していた。

LSTCは在宅勤務OK、なので「寒くない所」を選んだようだ。

アリゾナは、今から22年前に一度だけ行ったことがある。太陽が眩しくてサングラスなしでは

何も見えなかったような、そして周囲はデカいサボテンだらけ、だった記憶。これは1996年

距離感はハンパじゃない。

住所も教えてくれたので、Google Mapで調べたら、こんな風景? 裏庭にはコヨーテが来るらしい。

(向こう側が、新興住宅街? になっていて、そのあたりの雰囲気)

セミナスナップショット。セミナ中の撮影は結構できないから、これ一枚だけ。

LSDYNA R11.0

2018 年 10 月 2 日 火曜日R10.1 WinSuite版

LS-OPT等LSTC社製品殆ど+多くの例題を含んだWindows用インストーラ。

2017/10/23紹介のR10.1版です。

LS-DYNA/R10.1 にありますが、容量が大きい(約900MB) です。

R11.0

今年8月終わりに Linux版から出始め、全OS用の実行モジュールが出揃い、リリースノートも

公開されたので、最新バージョン R11 を紹介します。

実行モジュールは、ダウンロードサイトの LS-DYNA/R11.0 にあります。

正式マニュアルは未だのようで、最新DRAFT版が manual/DRAFT にあります。

未だリリースされていないもの:Windows版インストーラ版、正式マニュアル

R11.0実行には、ライセンスの更新(R11.0実行権付加)が必要です。

R11.0リリースノート

私が実際試した印象では、Implicitソルバ(特にMPP版)が大きく変わっていました。

詳細は幾つかテストして結果をお知らせします。以下リリースノート、、、長いです。

---------------------------------------------------------------------------------

This file constitutes revision 0 of the release notes for LS-DYNA version R11.0.0

---------------------------------------------------------------------------------

I. LICENSE

The string “REVISION 11” must appear in the LS-DYNA license file in order to run

version R11.0.0. Please contact your LS-DYNA distributor (keys@lstc.com if

you’re a direct customer of LSTC) if you need to have your license updated.

—————————————————————————-

II. DOCUMENTATION

Until such time the R11.0 User’s Manual is posted at www.lstc.com/download/manuals,

the DRAFT User’s Manual at www.lstc.com/download/manuals may be used as a

temporary substitute, but please be aware that there may be features mentioned in the DRAFT

User’s Manual which are not implemented in version R11.0.0.

—————————————————————————-

III. NOTES

The remainder of this file provides a brief description of new features and

enhancements in version 11.0.0. Some bug fixes are also described, some of

which may also have been included in release notes of prior versions.

The items are arranged by category. Understand that in many cases,

a particular item may pertain to more than one category, but in the

interest of brevity, each item is listed only once, under a single category.

Excluding the “Miscellaneous” category, the categories are arranged alphabetically.

The categories are:

*AIRBAG

ALE

*BOUNDARY

Blast

CESE (Compressible Fluid Solver)

*CHEMISTRY

CONTACT

*CONSTRAINED

*CONTROL

Discrete Element Method

EFG (Element Free Galerkin)

*ELEMENT

EM (Electromagnetic Solver)

Forming Analysis

*FREQUENCY_DOMAIN

ICFD (Incompressible Fluid Solver)

Implicit (Mechanical) Solver

*INITIAL

Isogeometric Elements

*LOAD

*MAT and *EOS

MPP

Output

Restarts

*SENSOR

SPG (Smooth Particle Galerkin)

SPH (Smooth Particle Hydrodynamics)

Thermal Solver

XFEM (eXtended Finite Element Method)

Miscellaneous

==============================================================================

________________________ *AIRBAG ___________________

Fix an airbag bug that can cause MPP to hang when reference geometry is used in a huge model.

Limit the EXCP option (excluding application of bag pressure to partition parts) in

*AIRBAG_INTERACTION to *AIRBAG_WANG_NEFSKE and *AIRBAG_HYBRID only.

Allow no-pressure venting parts for *AIRBAG_WANG_NEFSKE.

Output material leakage information, including leakage rate, in abstat for

*AIRBAG_WANG_NEFSKE.

Allow airbag venting holes of *AIRBAG_HYBRID to be represented by a part set.

Enhance the robustness of *AIRBAG_INTERACTION to curtail instability, especially in MPP,

due to excessive mass exchange owing to numerical noise.

Support UP (uniform pressure) airbag in MPP full deck restart.

(We use the equivalent terms UP airbag or CV (control volume) airbag for

airbags that are NOT based on ALE or particle (CPM) methods.)

Treat PPOP for *AIRBAG_WANG_NEFSKE similar to other types of UP airbag – once it pops,

it stays open.

*AIRBAG_CPM_INTERACTION:

– Support slave bag with chamber definition.

– Support master/slave bags having multiple gas components.

New CPM (*AIRBAG_PARTICLE) particle-to-fabric and particle-to-particle contact algorithms.

These are about 3x faster than the old scheme and it is the default method

without any input modifications.

Support *SENSOR_SWITCH_SHELL_TO_VENT for SMP.

New variable TSPLIT in *AIRBAG_PARTICLE to activate particle splitting.

Particles that exit by porosity leakage or a vent are removed from the

system. If TSPLIT is set, the code keeps track of the number of removed parti-

cles (A) and active particles (B) every 200 cycles after time TSPLIT. Once A is

greater than B, each active particle will be split into A/B + 1 particles for a bet-

ter particle density in the volume.

Enable OpenMP. This allows MPP hybrid to scale better.

Support the exterior air drag force capability while switching from particle to UP formulation.

Enable *DEFINE_FUNCTION for user to control the airbag particle deflection angle.

Three airbag history variables are passed to the user defined function to control the surface roughness:

bag pressure, bag volume, current time.

Support *MAT_ADD_AIRBAG_POROSITY_LEAKAGE

Support FAC in the option can be defined as a factor/define_curve/define_function

If defined_function, it only works with vopt 7/8. the porosity leakage velocity is a function of

current part pressure and time.

Support molar-fraction-based inflator gas flow rate curve LCMASS (MOLEFRACTION option)

even after particle airbag switches to CV airbag via the TSW switch.

Enhance dm_out calculation to treat trunction error.

Support specification of inflator orifice area as function of time to control the

distribution of mass flowrate.

Fix bug affecting particle-to-UP switch for multi-chambered airbag.

The bug was introduced in r82352 and showed up if gas contains multi-species.

*AIRBAG_LINEAR_FLUID:

Prior to R11, the tangent stiffness matrix resulting from a pressure-volume relationship

in simple airbag models was merely an approximation and sometimes resulted in poor

convergence. A justification of the approximation is that a rigorous treatment reveals

that coupling terms between all nodes in bag result in a dense stiffness matrix and slow

execution. Exploiting the low rank structure of this matrix contribution and the use of

Sherman-Morrison formula, the correct (or at least close to correct) stiffness matrix is

now implemented without sacrificing speed and at the same time obtaining much

better convergence.

________________________ ALE ___________________

*ALE_STRUCTURED_MESH_CONTROL_POINTS:

If the S-ALE mesh has different mesh sizes and transition zones, suggest new lists of

control points to create optimal mesh transitions (the new list is output in

the messag file).

*ALE_STRUCTURED_MESH:

2D version of the S-ALE code.

*ALE_INJECTION:

Inject materials in an ALE mesh (i.e. add a group to some elements and

prescribe the velocities of the related nodes).

*ALE_PRESCRIBED_MOTION:

Prescribe or initialize velocities by ALE group.

*ALE_FSI_TO_LOAD_NODE:

Use the 2nd line for a directory path where to read or write the files with the

fsi data (alefsi2ldnd*.tmp*). Implement the restart.

*CONTROL_ALE and *SECTION_ALE2D_SMOOTHING

mpp version of the AFAC, BFAC, CFAC and DFAC mesh smoothings in the 2D ALE code.

*CONTROL_ALE (END<0, 2nd line, 2nd column):

If END<0 in *CONTROL_ALE, remove the ALE mesh after |END|.

*CONTROL_ALE (IALEDR=1, 4th line, 2nd column) and *CONTROL_DYNAMIC_RELAXATION:

Exclude ALE computations if IDRFLG=1 unless IALEDR=1.

*MAT_ADD_EROSION (IDAM>0, 1st line, 3rd column):

Implement the GISSMO damage model in ALE.

*DATABASE_ALE_MAT:

Output the volume averaged pressures of each ALE groups

*INITIAL_DETONATION and *CONTROL_EXPLOSIVE_SHADOW:

Compute the lighting times by ALE explosive groups.

*DATABASE_ALE_BINARY:

Output ALE data in a binary file that can be post-treated.

*CONTROL_MPP_DECOMPOSITION_DISTRIBUTE_ALE_ELEMENTS (ALECOMM=1, 1st line, 2nd column):

Create a MPP communicator for processors involved in ALE applications.

Added *ALE_STRUCTURED_MESH_TRIM so initial mesh can be trimmed to better fit the

domain of interest.

S-ALE mesh starts from a rectangular box and the elements away from the domain of interest

are then deleted based on the distance to certain geometry or part/element set.

This way S-ALE mesh could be of irregular shape. Fewer elements leads to less running time.

Added *ALE_STRUCTURED_MESH_MOTION so S-ALE mesh can be made to follow the motion

of the mass center of certain ALE material material(s).

Add variable TDEATH in *ALE_STRUCTURED_MESH so S-ALE mesh can be deleted during

the run to save running time. All related FSI and nodal coupling cards are

automatically deleted too.

Fix bugs affecting S-ALE (*ALE_STRUCTURED_MESH):

– Fix sometimes improper volume fraction initialization by *INITIAL_VOLUME_FRACTION_GEOMETRY

when using with ESORT=1 in *CONTROL_SOLID.

– Fix sometimes incorrect effect of *INITIAL_HYDROSTATIC_ALE and *ALE_AMBIENT_HYDROSTATIC

when using with ESORT=1 in *CONTROL_SOLID.

________________________ *BOUNDARY ___________________

Speedup the input error checking for *BOUNDARY_PRESCRIBED_MOTION.

Fix *BOUNDARY_PRESCRIBED_ORIENTATION_RIGID_DIRCOS which did not orientate the

rigid body when angles are close to PI when using double precision.

*BOUNDARY_CYCLIC is supported in selective mass scaling (*CONTROL_TIMESTEP).

*BOUNDARY_SPC_SYMMETRY_PLANE:

– Add a new option _SET.

– Allow more than two definitions of symmetric planes.

– Fix core dump when *BOUNDARY_SPC_SYMMETRY_PLANE, and *ALE_MULTI-MATERIAL_GROUP

are used together.

________________________ Blast ___________________

For *LOAD_BLAST_ENHANCED BLAST=4, apply blast pressure to segments which reside

below the ground plane with new parameter FLOOR. This allows blast pressure

to be applied to a deformable floor which deflects below the ground plane, and

accomodates floors which are not planar.

Implement blast particle-SPH coupling algorithm as invoked by variable NODID in

*DEFINE_PARTICLE_BLAST (SMP). The SPH smoothing length is taken into

consideration.

________________________ CESE (Compressible Fluid Solver) ________________

Added a new prescribed boundary condition card that allows a normal

velocity to be specified in the inlet boundary.

Added a positivity-preserving strategy for the spatial derivatives

calculations to make the solver more stable (currently only CESE 2D,

3D, and CESE-FSI-IBM 2D solvers are supported).

Made it a fatal error to attempt to use *LOAD_BLAST_ENHANCED as a

CESE boundary condition with other than a type-2 blast.

Improved error tolerances in the conjugate heat transfer method

solver used with the immersed-boundary method FSI solver, and

corrected other small related errors.

Any unused nodes specified in a standalone CESE problem are now

treated as a fatal error. This fixes an issue with d3plot output

when such orphan nodes were passed on to the d3plot file.

Corrected some weightings for the MPP CESE moving mesh solvers.

This could have been an issue in cases where an MPP CESE shared

node is next to a moving boundary.

Adjusted the information output by the implicit ball-vertex mesh

motion solver to reflect that the absolute error tolerance is no

longer used, only the relative error tolerance. This applies

to both the ICFD and CESE solvers that use this mesh motion solver.

For the *CESE_DATABASE cards, corrected these issues:

a) Any used segments that are not in the CESE mesh are reported.

b) Element sets look up is now guaranteed to work.

c) Drag calculation output that is attempted for the incorrect FSI method,

is now reported. Here are the illegal cases:

i) *CESE_DATABASE_FSIDRAG is only available with the CESE immersed

boundary FSI solvers.

ii) *CESE_DATABASE_SSETDRAG is not available with the CESE immersed

boundary FSI solvers. In other words, it only works with the

non-FSI solvers and moving mesh FSI solvers.

d) Failure to find an internal node number in *CESE_DATABASE commands is now

reported.

e) Output was not being performed for the initial conditions. Instead, it

is now done after the first time step.

f) Warning is given when illegal IDs are given in *CESE_DATABASE… cards.

Such IDs are then ignored.

Changed behavior for the *CESE_DATABASE cards includes:

a) Output times are now selected in a manner similar to CESE d3plot output,

meaning when the CESE simulation time has reached at least the requested

output times. Also, output never occurs more than once per CESE time step.

b) Cycle number was reported in some outputs as the ‘time step’. The actual

solver time step is now used instead.

When performing d3plot output for the immersed boundary CESE FSI solver,

take into account what structural elements overlay CESE elements for the

Schlieren number and chemical species mass fractions.

Formation enthalpy concept is added to the CESE Navier-Stokes solver.

Many restart-related bugs were fixed in various CESE solvers.

CESE immersed-boundary method (IBM) FSI solvers now work with adaptive

shell problems.

________________________ *CHEMISTRY ___________________

The chemistry solvers are working with the following CESE solvers:

a) 2D, 3D, and axi-symmetric Euler and Navier-Stokes solvers.

b) Immersed boundary method FSI 2D, 3D, and axi-symmetric Euler solvers.

Added a restart capability for the CESE chemistry solvers.

________________________ CONTACT ___________________

Fix initialization error related to *CONTACT_GENERAL_INTERIOR

that resulted in every subsequent *CONTACT_GENERAL also being

treated as INTERIOR.

Fix for spotwelds improperly deleted due to

rigid body conflict when an IPBACK contact interface

is in effect. The failure of the constraint-based

contact to tie should not cause the weld

to be deleted if the penalty-based contact ties.

Fix reported contact forces and energies for

*CONTACT_TIED_SHELL_EDGE_TO_SOLID.

Fix bug for *CONTACT_ERODING_NODES_to_SURFACE. The slave nodes’ thickness was ignored,

which was problematic for SPH simulations, for example. SST is now taken into account for this contact.

Fix a problem with SMOOTH contact during implicit springback.

Enhance implicit processing of tied contact and rotational dofs on slave nodes

for special cases with *CONTACT_…_CONSTRAINED_OFFSET.

Adjust logic for unconstraining rigid body slave nodes for SMOOTH contact

to be compatible with deformable to rigid switching.

Enable the use of *CONTACT_FORMING_…_SMOOTH for implicit.

Fix the problem of tied contact in MPP having a slave node from another

process working with new approach for tied contact.

Correct initialization of MPP tied contact with implicit mechanics when

explicit is running dynamic relaxation followed by implicit.

Fix a bug in assignment of contact thickness for null beams.

This bug was introduced at r89658/R9.

Add variable 2DBINR (Card F) for surface-to-surface contact involving 2D seatbelt elements

initially inside a retractor. This is only available for SOFT=2 contact.

Fix a bug for contact involving high order shell elements that occurs when 8-node

shell elements are generated by SHL4_TO_SHL8, or when using large part id like 100000001.

Add an alternative implementation of ICOR (coefficient of restitution) for contact.

The algebraic sign of ICOR determines which implementation is used.

Command line option, soft=1to2 converts all possible contacts from soft=1 to soft=2

Command line option, soft=2to1 converts contacts from soft=2 to soft=1

Fix *CONTACT_AUTOMATIC_GENERAL for spotweld beams when using SSID=0, i.e. all

parts included in the contact, and CPARM8=2.

Implement unloading curve, UNLCID, for options FCM=2/3 in *CONTACT_RIGID_(OPTION).

Fix zero frictional energy output to glstat and sleout when using

*CONTACT_AUTOMATIC_SURFACE_TO_SURFACE_ORTHO_FRICTION.

Implement SMP consistency mode, i.e. ncpu<0, for:

– *CONTACT_SURFACE_TO_SURFACE_CONTRACTION_JOINT

– *CONTACT_AUTOMATIC_SURFACE_TO_SURFACE_COMPOSITE

Fix seg fault when using *CONTACT_AUTOMATIC_NODES_TO_SURFACE for SPH elements

impacting on shell plate.

Fix *DEFORMABLE_TO_RIGID switching using contact forces, CODE=2 & 4, when the

contact type is *CONTACT_FORCE_TRANSDUCER.

Fix zero contact stiffness if *EOS_TABULATED is using curve LCC

instead of tabulated input cards.

Allow *CONTACT_TIED_SURFACE_TO_SURFACE to use MAXPAR in Optional Card A

It was previously hardcoded to 1.01.

Implement edge treatment option SRNDE=1,2 (Optional Card E) for *CONTACT_AUTOMATIC_NODES_TO_SURFACE.

Fixed MPP segment based (SOFT=2) contact when used with 2-surface force transducers.

Output data may have been incrrect due to errors in accessing arrays. This error

occurred when different processors participate in different contact interfaces.

Fixed MPP implicit SOFT=2 contact which was failing to properly reset the segment

and node data from a converged state leading to possible “floating invalid” error

or possible convergence failure.

Fixed an MPP SOFT=2 contact problem that could occur if a contact interface used

SBOXID to eliminate slave segments. This could cause a segmentation fault during initialization.

Fixed a possible memory error during initialization of SOFT=2 contact, when using

DEPTH=5, 15, 25, or 35 or SBOPT=4 or 5.

Fixed an error in MPP SOFT=2 eroding contact that could cause force spikes and inappropriate

contact detection after solid elements erode.

Fixed an error in SOFT=2 eroding contact that caused the contact to fail to create

new segments on interior elements when there were no active segments at the start of the run.

This error was most likely to occur in MPP runs when a decomposition can result in a process

that has no active segments at the start of the run.

Changed the behavior of SOFT=2 contact when the contact keyword indicates a surface to surface

contact, but the master surface has no segments. In older versions, the contact would use the

slave segments and do a single surface contact with them. Going forward, the contact will

not do anything because the slave surface has nothing to contact.

Fixed some contact options when using linear 3D solids or linear shell elements in implicit analysis.

These element were causing a zero explicit time step, and some contacts use this explicit step in

the denominator of the stiffness matrix. These include SOFT=1, SOFT=2, and tied, penalty-based contacts.

Added a gap calculation to SOFT=2 contact. The gaps are written to the binary interface force file.

This is supported for both SMP and MPP. Overlaps are reported as negative gaps.

Fixed a flaw in the support of SSF on *PART_CONTACT when using SOFT=2 contact with DEPTH=5.

The consequence was to sometimes choose the wrong part when looking up the scale factor so

the stiffness was not predictable.

Added variable SSFTYP on card F of *CONTACT which affects how SSF on *PART_CONTACT works when used

with SOFT=2 contact. By default, the contact chooses a master segment for each pair of segments

in contact. The SSF factor is then taken from the slave segment. When SSFTYP is set to 1 (or any

nonzero value), it changes the behavior so the maximum SSF value of the 2 segments in contact will be used.

The contact stiffness is therefore independent of how the contact chooses master and slave segments.

Fixed MPP *PART_CONTACT when used with SSF. It was possible for SSF to be incorrectly taken

as zero, so penetration would occur.

Improved the accuracy of *CONTACT_2D_AUTOMATIC contact. For problems where penetration depths

are small, there was an accuracy issue that could cause contact forces to be set to zero in cycles

when they should not have been, which could cause a loss of contact history. Because the

penetrations are small, the results look about the same, but the contact pressure history is smoother.

Fixed *CONTACT_2D_AUTOMATIC so it will correctly add new segments when elements using

*MAT_081 or*MAT_082 are used for an eroding part.

Fixed *CONTACT_2D_AUTOMATIC_TIED which could could fail if more than 1 tied contact

was used in a model.

Fixed the sliding option, ISLIDE, of *CONTACT_2D_AUTOMATIC type contacts in both SMP and MPP.

Fixed MPP *CONTACT_2D_AUTOMATIC_SINGLE_SURFACE and *CONTACT_2D_AUTOMATIC_SURFACE_TO_SURFACE

which had a problem in the bucket sort where the buckets may have been too small if

segments passed from other processors were larger than the segments already in the processors.

This could cause some contact to be missed. It could also cause the job to terminate with

Error SOL+1274 if the passed segments are large enough such as can occur with shooting nodes.

Added an option to offset the contact surface segments attached to 2D solid elements

in *CONTACT_2D_AUTOMATIC. The option is controlled by two new parameters, SLDSOS and SLDSOM,

on new optional card 5. If the card is omitted, or SLDSOS or SLDSOM are input as zero, then

there is zero offset which has always been assumed for surfaces of solids. If input with

a value greater than zero, then the offset is set equal to the input value. This behavior

is not consistent with the 3D SLDTHK option, which uses half the input value, but it is

consistent with the negative value option of SOS and SOM on card 2 which uses the input value,

not half of it.

Add option NEHIS to *USER_INTERFACE_FRICTION:

– With NEHIS=0 (default), special choice of element history

variables is provided in subroutine usrfrc, see comments there.

– With NEHIS>0, plastic strain and element history variables

up to NEHIS-1 are provided in original order in subroutine usrfrc.

Add new *CONTACT_AUTOMATIC_…_TIEBREAK model OPTIONs 13 and 14,

which are based on *MAT_240.

Allow unlimited number of history variables for user-defined tiebreak,

*CONTACT_AUTOMATIC_ONE_WAY_SURFACE_TO_SURFACE_TIEBREAK_USER.

IGNORE=2 on *CONTACT_…_MORTAR is set to default to avoid unnecessary bad behavior.

If ISYM<0 on *CONTROL_CONTACT, this will point to a node set

containing all nodes on symmetry planes in the model, which will be

picked up by the mortar contact and treat edge treatment accordingly.

If MPAR1<0 on *CONTACT_…_MORTAR for IGNORE=3, this will govern the

penetraction reduction as a function of a curve.

If SLDTHK<0 on *CONTACT_…_MORTAR, the contact surface is offset “inwards”,

previously only a positive value was supported.

Implicit tied contacts (strong objective) supported for groupable option,

which is necessary when running a coupled thermal/mechanical simulation.

User friction supported in mortar contact, see *USER_INTERFACE_FRICTION.

The subroutine is called mortar_usrfrc and found in dyn21.F.

FS=2 on *CONTACT_…_MORTAR supported, allowing friction as function of

sliding velocity and contact pressure in mortar contact.

For large penetrations in mortar contact during implicit analysis, the

step will be abandoned and a retried with a smaller time step.

*CONTACT_AUTOMATIC_SURFACE_TO_SURFACE_MORTAR_TIED_WELD supported, SMP and MPP,

particularly intended for implicit.

When mortar tied contact is used with shells, offsets are accounted

for to induce a moment from tangential tractions in the interface.

In mortar contact, let PENMAX and SLDTHK take over the meanings SST

and TKSLS have in R9 and earlier, although in a different way. Now

PENMAX corresponds to the maximum penetration depth for solids.

SLDTHK is used to offset the contact surface from the physical

surface of the solid element, instead of playing with SST and

TKSLS, which was rather awkward. This update also saves the

pain of having to treat shells and solids in separate interfaces

if these features are desired.

A “shooting node logic” algorithm is implemented for mortar contact,

and is always active. This should reduce the presence of negative

sliding energies when run in explicit and also improve

initial penetration situations in implicit.

The MPP groupable contacts include all eroding contacts, i.e.

*CONTACT_ERODING_NODES_TO_SURFACE

*CONTACT_ERODING_SURFACE_TO_SURFACE

*CONTACT_ERODING_SINGLE_SURFACE.

The MPP groupable contacts include beam-to-beam treatment in *CONTACT_AUTOMATIC_GENERAL.

It supports rectangular beams, and output of contact forces to rcforc for an

accompanying 2-sided force transducer.

The MPP *CONTACT_AUTOMATIC_SINGLE_SURFACE_TIED is implemented and supports parameter CLOSE.

MPP’s *CONTACT_AUTOMATIC_BEAMS_TO_SURFACE_ID now supports the contact of slave beam

nodes from both sides of the master surface.

Fix incorrect *INITIAL_STRESS data written to dynain in MPP when np>1.

*CONTACT_FORMING_ONE_WAY_SURFACE_TO_SURFACE:

Improve SOFT=6 behavior. In guide pin contact, consider the pin’s curved edge,

therefore overcome the false penetration problem.

*CONTACT_FORMING_NODES_TO_SURFACE_SMOOTH:

Allow segment definition, in addition to part or part set ID.

________________________ *CONSTRAINED ___________________

Fix MPP message passing error that could occur

if a node involved in *CONSTRAINED_SHELL_TO_SOLID

is shared between more than 2 processors.

*CONSTRAINED_GLOBAL: Added user-defined tolerance parameter TOL in length

units. If non-zero, the internal mesh-size dependent tolerance gets

replaced by this value.

Added option to continue a calculation with constrained interpolation after an

indpendent node is deleted using INDSW in *CONSTRAINED_INTERPOLATION.

Fix to exactly singular constraint matrix for *CONSTRAINED_INTERPOLATION

running in fast/vector mode.

Correct MPP communication during the detection of co-linear nodes in *CONSTRAINED_INTERPOLATION.

Add additional error checking on coincident nodes for revolute and screw joints.

Promote linear algebra processing for *CONSTRAINED_INTERPOLATION in

explicit single precision to real*8 to remove round-off accumulation

errors.

A more robust solution to the processing of birth and death times for

prescribed motion constraints for the LaGrange Multiplier Formulation

of joints for explicit.

Add implicit capabilities pertaining to UNITCELL:

– Always unconstrain the last 3 nodes in input and output if they are referenced

in *CONSTRAINED_MULTIPLE_GLOBAL constraints. These are control points

for UNITCELL.

– At the end of implicit time step always go through the computation to

compute the resultant forces. If there are *CONSTRAINED_MULTIPLE_GLOBAL

constraints, output the resultant forces on the last 3 nodes.

Enhance nodal constraint handling for superelements

using explicit to properly handle the implicit/explicit switching

case. I also extended the code to recognize *BOUNDARY_SPC

definitions instead of just those on the *NODE cards.

The logic to handle *CONSTRAINED_INTERPOLATION with large number of independent nodes

extended for *CONTROL_IMPLICIT_MODES.

Implicit was enforcing birth and death times on *BOUNDARY_SPC during dynamic

relaxation contrary to the manual. So such times are now ignored with dynamic

relaxation.

Added a warning about the combined use of rigid body stoppers and the

lagrange multiplier formulation of joints for explicit recommending

switching to the penalty formulation.

Corrections to get implicit to work with *CONSTRAINED_INTERPOLATION with lots

of independent nodes especially in MPP.

*CONSTRAINED_BEAM_IN_SOLID:

– Add _PENALTY option to invoke a penalty-based formulation (implicit and explicit).

– Implicit support for IDIR=1 (allow sliding along axial direction).

– Implicit support for AXFOR (user prescribed debonding force between beam and solid).

– Thermal solver recognizes *CONSTRAINED_BEAM_IN_SOLID by constraining temperature

fields between beam and solid nodes.

– Write LSDA format output file named “cbisfor” containing debonding force

(constraint-based) or penalty force (penalty-based).

Add two keywords *CONSTRAINED_SHELL_IN_SOLID and *CONSTRAINED_SOLID_IN_SOLID,

which are similar to *CONSTRAINED_BEAM_IN_SOLID, but are used to couple

shells immersed in solids and solids immersed in solids, respectively.

Fix a bug affecting *CONSTRAINED_LOCAL whereby z-translation was mistakenly constrained when IRC=0.

Fix a bug for PIDCTL of *DEFINE_CURVE_FUNCTION, that occurs when using “0” as sampling rate.

*CONSTRAINED_SPOTWELD:

Enable the normal and shear forces at spotweld failures to be temperature-dependent functions.

Allow the same part to be used in SPR connections, i.e.,

MID and SID can now match in *CONSTRAINED_SPR2 or rather

PID1 and PID2 can match in *CONSTRAINED_INTERPOLATION_SPOTWELD.

The requirement for this is that the SPR node lies in between the

shell elements to be self-connected.

*CONSTRAINED_INTERPOLATION_SPOTWELD, MODEL=1,

can now be used as connection of two beam nodes.

Several updates for *CONSTRAINED_INTERPOLATION_SPOTWELD (new card 5):

– Incorporate torsion mode with GAMMA>0.

– Allow definition of separate stiffnesses STIFF, STIFF2, STIFF3,

and STIFF4 for tension, shear, bending, and torsion.

– Optional exponential damage law via LCDEXP.

– Alternative shear kinematics treatment, parameter SROPT.

– Output of history variables with NEIPB=7 on *DATABASE_EXTENT_BINARY.

Add GISSMO damage as failure variable for *CONSTRAINED_TIED_NODES_FAILURE.

Fixed bug in processing *CONSTRAINED_NODAL_RIGID_BODY and *PART_INERTIA

so code does not abort with a bogus “Error 10144”.

*CONSTRAINED_COORDINATE:

– Fix a machine dependent error when the input coordinates are far away from the part.

– Extend to rotational constraints. The constraint will be appled to the closest node.

When IDIR>10, IR = IDIR-10:

IR=1, constrain rx

IR=2, constrain ry

IR=3, constrain rz

IR=4, constrain rx+ry

IR=5, constrain ry+rz

IR=6, constrain rz+rx

IR=7, constrain rx+ry+rz

– Fix a segmentation fault problem when IDIR is greater than 10.

*CONSTRAINED_RIGID_BODY_STOPPERS:

Extend to have multiple rigid body stoppers for one single rigid body.

________________________ *CONTROL ___________________

*CONTROL_REFINE_SOLID and *SECTION_SOLID (ELFORM=2):

Support fully integrated S/R solids.

*CONTROL_REFINE_… (IBOX, 1st line, 5th column):

Implement *DEFINE_BOX_LOCAL and *DEFINE_BOX_ADAPTIVE to refine elements

checking criteria provided by these box keywords.

*CONTROL_ADAPTIVE (ADPOPT=8, 1st line, 3rd column) and *SECTION_SHELL (ELFORM=12):

Map the plain stress shell thicknesses for the 2D adaptive remeshing

Staged construction (*CONTROL_STAGED_CONSTRUCTION, *DEFINE_STAGED_CONSTRUCTION_PART):

Change the behaviour when a part is added.

Previously, the stiffness and strength of the part would ramp up gradually

according to ramp time ATR on *DEFINE_CONSTRUCTION_STAGES. Now, the stiffness

and strength have their full value immediately at the start of the stage when

the part becomes active (STGA). The reason for the change is to prevent unrealistic

deformations occurring while the part is only partially stiff. The same change

applies if a part is added using STGA on *LOAD_STIFFEN_PART. There is no change

to gravity loading associated with *DEFINE_STAGED_CONSTRUCTION_PART:

when a part is added, the gravity load still ramps up according to ramp time ATR.

Nor is there any change to the behaviour during part removal.

Other updates to Staged Construction are:

– Enabled _TITLE option for

*DEFINE_CONSTRUCTION_STAGES and *DEFINE_STAGED_CONSTRUCTION_PART. The titles

are ignored by LS-DYNA, and are used only in pre-processing. Previously,

adding _TITLE would have caused an input error.

– Fixed bugs in energy balance output for

staged construction (*DEFINE_STAGED_CONSTRUCTION_PART and also

*LOAD_STIFFEN_PART and *LOAD_GRAVITY_PART). The internal energy was wrongly

calculated for dormant parts, and the gravity loading could sometimes be

missing from the external work calculation, depending on the other contents

of the model. These bugs affected the energy outputs (e.g. in glstat file)

but did not affect the other results (stress, displacement, etc).

– Fix bug in dynain file related to the format of *INITIAL_PWP_NODAL_DATA card,

which is written if the model contains *CONTROL_PORE_FLUID. The resulting dynain

file could not be read into LS-DYNA.

– *DEFINE_CONSTRUCTION_STAGES have option inputs RTS, RTE (“real time” at

start and end of stage). This is intended to enable an “accelerated analysis”

in which processes that really take days or weeks can be modelled in

seconds of analysis time. These inputs previously had no effect, they were

present only to help the user understand the times in the input file. Now,

“real times” will be written to the output files in place of analysis time.

– Fixed bug that occurred with *CONTROL_STAGED_CONSTRUCTION

if Dynamic Relaxation was also switched on. Staged construction is compatible with

D.R. only if the analysis begins at the first stage (i.e. time=0). If not, D.R. now

gets switched off automatically and a warning is issued.

– Enabled *LOAD_GRAVITY_PART for tshells.

— CONTROL_ADAPTIVE —

Fix to avoid segfault in R-adaptivity

if 2*(number of shells) > 3*(number of nodes).

Fix problem with 2d adaptivity and boundary merging.

Some boundary points between materials

weren’t merged in some cases, depending on where the

program thought the 2d contours started. This

only applies for *CONTROL_ADAPTIVE adpopt=8

with mmm2d=1.

Fix excessive memory growth during adaptive problems, and reduce

memory requirements overall.

Generate input error message if *DEFINE_FILTER is used

together with *CONTROL_ADAPTIVE, because these filters

just won’t work with adaptivity.

Increase the size of some statically allocated

arrays so that larger 2d adaptive problems can be

run.

*CONTROL_ADAPTIVE:

Added Card 5 with only one input variable called INMEMORY.

EQ.0: conventional out of core shell adaptivity

EQ.1: in-core shell adaptivity with load rebalancing.

*CONTROL_IMPLICIT_ROTATIONAL_DYNAMICS:

– The VID of the rotating axis can now be defined by both *DEFINE_VECTOR

and *DEFINE_VECTOR_NODES. It enables the movement of the rotating axis.

Previous verion only use *DEFINE_VECTOR to define the VID.

– The rotational dynamics can work in MPP now.

Added variable ICRFILE in *CONTROL_OUTPUT so that nodes sets and

element sets associated with *DATABASE_CROSS_SECTION are written to

a file to facilitate checking of the cross-section definition.

The adaptive element size range defined by RMIN/RMAX in *DEFINE_BOX_ADAPTIVE can

now be out of the range defined in *CONTROL_REMESHING for 3D adaptivity.

*CONTROL_ADAPTIVE:

Add warning message that IREFLG is not supported in 3D adaptivity (ADPOPT=7).

*CONTROL_ADAPTIVE:

– Add a new feature to the adaptivity of sandwich part: allow multi-layers of solid core to be refined.

– Support the refinement of 6-node solid elements in the refinement.

– Fix a bug in the output of ‘adapt.msh’: an extra blank line was output in *ELEMENT_SHELL_THICKNESS.

– Fix a duplicate beam error with adaptivity involving beam elements.

*CONTROL_ADAPTIVE_CURVE:

Fix a bug where the refinement width control was not functioning properly.

________________________ Discrete Element Method ___________________

Switch material type from rigid to elastic for DEM.

Enhance MPP’s particle-DEM coupling algorithm for *PARTICLE_BLAST.

Fix bug if de_massflow_plane and interface force file for

*DEFINE_DE_TO_SURFACE_COUPLING are both defined.

Fix MPP bug for *PARTICLE_BLAST if some processors contain solid

elements while other processors have no solid elements.

Fix bug for *PARTICLE_BLAST if solids are used as geometry for HE particles.

Implement rebalancing algorithm for *PARTICLE_BLAST, the performance of

particle-particle contact and particle-structure contact is increased by

~10~30 times for hundreds of cores—-MPP only.

Fix bug for *DEFINE_DE_MASSFLOW_PLANE output error if multiple planes

are defined.

Fix bug for *DEFINE_DE_INJECTION if multiple injection planes are defined.

Implement eroding coupling between particle and structure (shell/solid)

for *PARTICLE_BLAST. New surfaces of eroded solid parts are taken into

consideration.

Fix MPP bug when detonation point is defined using a node for *PARTICLE_BLAST.

Fix wear depth calculation error for DEM interface force file (MPP only).

Skip *PARTICLE_BLAST calculation during dynamic relaxation phase.

Fix MPP bug when there are multiple *PARTICLE_BLAST definitions.

Add calculation of coordination number for DEM in MPP.

Add automatic bucket sort for *DEFINE_DE_TO_SURFACE_COUPLING.

Reformualte particle injection algorithm for MPP such that

particles with different radii can be injected.

Add birth time and death time for *CONTROL_DISCRETE_ELEMENT.

Fix bug in calculation of capillary force for *DEFINE_DE_TO_SURFACE_COUPLING.

Fix bug for capillary force calculation if DEM model has zero potential

contact pairs but non-zero capillary force.

Implement DEM mass output to interface force file for

*DEFINE_DE_TO_SURFACE coupling.

Add mass output for demrcf.

Add moment output to demrcf (SMP only).

Report damping energy for DE non-reflecting boundary conditions.

Implement explicit thermal modeling of DES (SMP only).

Implement user defined curve to get mass flow rate for

*DEFINE_DE_INJECTION.

Fix minor bug for *DEFINE_DE_TO_SURFACE_COUPLING when the thickness of shell

is much larger than segment size.

________________________ EFG (Element Free Galerkin) _____________

Variables STRFLG and INTOUT in *DATABASE_EXTENT_BINARY can now be turned on when

using 3D adaptivity on EFG solid.

Special decomposition is implemented for EFG shell formulation 41 to avoid the

memory error in MPP.

Automatically set IPS=0 (no pressure smoothing) for EFG solid formulation 41.

*MAT_076 is now supported for EFG shell formulation 44.

Fixed incorrect stresses in:

– Plane strain EFG formulation (shell type 43) in both explicit and implicit,

– Axisymmetric EFG formulation (shell type 44) in explicit.

________________________ *ELEMENT ___________________

*INTEGRATION_BEAM with different PIDs at each integration point: this was an existing

capability, but the time step calculation was overly conservative for cases where the

section contained a small proportion

of a stiffer material, such as the reinforcement in reinforced concrete. For

the same reason, LS-DYNA could add large amounts of mass-scaling unnecessarily.

The time step calculation has been improved to remedy this.

Fixed bug for beam elements ELFORM=2: with certain combination of inputs only,

the output forces and moments could be wrongly rotated about the beam axis. This affected

the output forces only, not the solution inside LS-DYNA. The error could take

two forms: (a) if IST on *SECTION_BEAM is non-zero, the output forces

and moments are supposed to be rotated into the beam’s principal axis

system, but this rotation could be applied to the wrong beam elements;

and (b) when no ELFORM=2 elements have IST, but the model also contains

beams with ELFORM=6 and RRCON=1 on the SECTION_BEAM card, some of the

ELFORM=2 elements could have their output forces and moments rotated by

one radian. These bugs are now fixed.

Speed up keyword for some models that use lots of

*ELEMENT_SOLID_TET4TOTET10 due to too many memory allocation calls.

*SECTION_BEAM: Added a flag ITORM for improved representation of torsional

modes which can be activated (ITORM=1) only if an eigenvalue analysis is

performed and which applies only to beam type 13. If ITORM is not active

(ITORM=0) the torsional inertia from structural analysis is used which may

result in too large eigenvalues related to torsional modes.

Added cubic solid element formulations 27,28,29 (*SECTION_SOLID).

Added section forces for higher order solid elements.

Added element deletion capability for higher order elements.

Correct issue with prescribed motion on superelements for explicit mechanics.

Enhance the application of damping to superelements for explicit.

Tune up output of consistent elemental mass matrices. Needed to capture

the lumped mass terms that had been removed. This code changes output

of the elemental mass matrices to include the lumped terms.

Enhance *ELEMENT_DIRECT_MATRIX_INPUT where the matrices for the same

superelement do not match in order.

SEATBELT:

– Fix MPP bug that could occur where there is more than one type-9 seatbelt pretensioner.

– Fix misprinted section number and material number for 2D belt error message.

– Limit the bending stiffness of *MAT_SEATBELT to implicit analysis only.

Warning will be issued when non-zero bending stiffness is defined for explicit analysis.

– Fix a MPP bug whereby incorrect belt material length information is output to d3hsp.

– Fix a bug that occurs when time-dependent slipring friction is used for 2D belts.

– Fix erroneous 1d seatbelt slipring message that has been there since version R8.0.0.

Enhance *DATABASE_RECOVER_NODE so that it works for shell form 23 with 3×3 integration.

*USER_NONLOCAL_SEARCH:

Provides an interface for gathering the history data of specified elements that surround

a 窶徇aster窶・element to average (or smooth) the history data of the master element.

The surrounding elements are determined using a user defined strategy. The type of averaging

is also user specified. Currently this keyword only works for solid elements.

– supports solid form 1, 16, 19, 21

– supports _ORTHO to search in material local abc directions

– enables user to define a nonlocal search in ellipsoid shape

Added cohesive element formulation -29 that defines the cohesive midlayer from the

average of surrounding shell normals. This fomulation is better suited for simulating normal shear.

Fixed absence of part mass in d3hsp for cohesive shell element formulation 29.

Fix memory error when using *NODE_THICKNESS_SET and also fix node set not found

error when using *NODE_THICKNESS_SET with *SET_NODE_INTERSECT.

Make *TERMINATION_DELETED_SOLIDS work with hex spot weld failures.

Fix seg fault when using shell type 15, axisymmeteric volume weighted, with

*MAT_EROSION and also materials with equation-of-states.

Fixed implicit accuracy when using higher order shell form 23. The element was

forced to use 3×3 integration but now supports both 2×2 and 3×3.

Modified discrete beam form 6 when it is defined with rotational stiffness, but no

rotational damping. This change adds a small amount of damping to prevent beams from

excessive oscillations which can cause error in the element strain measure.

Fixed the NREFUP option (*CONTROL_OUTPUT) when the ORIENTATION option of *ELEMENT_BEAM

is not active and some other options are not active. The NREFUP option is available for

beam types 1, 2, 11, 12, and 14.

Fixed the thinning of shell form 24 which was thinning about 33% more than it should

under large tensile strain.

Enabled adaptive tet meshing (ADPOPT=7 on *CONTROL_ADAPTIVE) to work for any reasonable

solid element form at the start of the calculation. Previously, the part could only be

tet meshed with form 13 elements, or else EFG solid elements 41 or 42, or the job would

crash at the first remap step. Now it should work with any structural element form.

Improved the accuracy of tetrahedral solid form 13. During rigid body translation,

some pressure could develop. Now it can translate pressure free, and therefore stress free.

Fixed beam elements when some elements in a part use *ELEMENT_BEAM_ORIENTATION, and some do not.

The affected beam forms are 1, 2, 11, and 14.

Modified the behavior of isotropic materials that are used in composites that are modeled with

tshell form 5. The oscillation check on the thickness stress was modified to directly check

stress rather than a total strain. For nonlinear materials, this is more reliable as it was

possible to miss the oscillations when checking strains. This should have little effect on

most solutions.

Fixed tshell forms 5 and 7 when used with total Lagrangian material models such as *MAT_002.

Large rotations were leading to incorrect strains and stresses.

Fixed tshell form 3 when used with the hyperelastic materials. The L matrix was in

the global coordinate system instead of the local system.

Changed the d3hsp output of 3-node triangular shell elements so that zero thickness

is reported for node 4. The inputted node 4 value was being output and included in the

element thickness calculation, but now it is ignored.

Fixed output of membrane shell form 5 when used with materials other than 34 and 134.

The stress and history data written to the d3plot file was wrong.

Fixed the behavior of CDL and TDL on *SECTION_DISCRETE when one of the nodes is

constrained by an SPC. Also, corrected the deforc output when CDL and TDL limits

are reached.

Fixed the strain output in eloutdet for higher order shell form 23.

Improvement of error checking of cohesive elements (solid forms 19/20/21/22).

In addition to checking for adjacent elements (shells, tshells or solids),

we now check for being part of a tied contact definition.

This eliminates a lot of unnecessary warning messages.

Fixed adaptivity (and restart) for tetrahedral solid formulation 13 by porting

nodal averaged data between adaptive steps. Before this fix, spurious peaks in

cross-section forces could occur and be mistaken for contact pressure peaks.

Add new option for *PART_STACKED_ELEMENTS to deal with in-plane composed

reference mesh parts. Has to be used together with *NODE_MERGE_SET.

Add cross section forces (*DATABASE_SECFORC) for 20-node and 27-node hexas,

i.e., solid forms 23 and 24.

Add variable ITOFF in *SECTION_BEAM to control torsion behavior for spotweld

beams (beam form 9).

Improve time step estimate for 10-noded tet form 16 with “curved” edges

to improve robustness.

Add variable ICRQ=2 on *CONTROL_SHELL to

only treat thickness continuously across element edges.

This is an alternative to ICRQ=1 which treats both thickness and plastic strain

continuously across element edges.

For higher order shells, the body loads account for

shape functions when assembling nodal forces.

The kinematics for warped/hourglassed cohesive solid forms 20/22 are

now corrected so that rigid body motion should give zero eigenvalues.

If IACC=1 on *CONTROL_ACCURACY, 6-node quadratic shell form 24 is treated

according to Martin & Breiner for alleviating membrane and shear locking.

If IBEAM on *CONTROL_IMPLICIT_EIGENVALUE is set to 2 or 13, then beam

formulations 1, 4 and 5 undergo section conversion from an integration

rule to resultant properties.

Fixed error for reading *ELEMENT_SHELL_OFFSET_COMPOSITE.

Fix parsing errors in *SECTION_BEAM_AISC.

Fix error in reading of user-defined shell elements.

A new 4-node tetrahedral solid element (ELFORM=60) is implemented to support mixed materials.

The volumetric locking is eliminated without nodal averaging.

________________________ EM (Electromagnetic Solver) ___________________

EM Analysis developments are divided into several subcategories below.

I. Batteries

Added 2 extra variables in d3plot in EM_FEMSTER_NODE for batteries:

D3PL_RAND_areaCircuit_EM

D3PL_RAND_areaCell_EM

For local area of each Randle circuit and global area of the cell.

Added meshless Randle model, see *EM_RANDLES_MESHLESS.

Fixed bugs for addition of joule heat rate in meshless Randle.

Added battery model with composite tshells.

Switched from *EM_CIRCUIT_RANDLE to *EM_BATTERY_RANDLES for solids and

*EM_RANDLE_LAYERED for composite tshells.

In *EM_BATTERY_RANDLES, *EM_RANDLE_LAYERED and *EM_RANDLE_SHORT,

Randle Area=2 is now the default, and the old Randle Area=0 (“as is”)

is now Randle Area=3.

Added cylindrical cells.

Fix bug in build of the layered (composite tshells) circuits when layers end

up by a separator (like in cylindrical cells).

Addition of RANDLES instead of RANDLE in *EM_RANDLE_… keywords to be

consistent with the manual (the old RANDLE still works).

Fix bug in building layer mesh for addition of different composite tshell parts.

Addition of Randle Area in randles circuit for composite tshells.

Addition of Randles circuit in connection with new LS-PrePost

battery packaging for solid elements, in serial and MPP.

Addition of optional joule heating from a meshless Randle

circuit to a set of parts (uniformly). This is triggered using

*EM_ISOPOTENTIAL_CONNECT.

II. Electrophysiology

Added Monodomain (EPMD) and bidomain (EPBD) solvers for electrophysiology.

Addition of bath loading in EP models, both in EPBD, and in EPMD,

using an augmented monodomain approach. This should work both in serial and MPP.

Added calcium concentration at nodes vector in EP so that it can be

used in mechanical models. It can be visualized using d3plot

in relative permeability for now.

Added PCG in EP: the user can choose between MF2 and PCG using EM_SOLVER_FEM.

Added tetrahedrons in EPMD and EPBD.

Addition of *EM_EP_TENTUSSCHER_STIMULUS2 to create stimulus on a node

set where the amplitude is time dependent given by a load curve

(amplitude vs time). Several such stimuli can be created at the same time.

Addition of user cards for *EM_EP_TENTUSSCHER and

*EM_EP_TENTUSSCHER_STIMULUS for user to input parameters for electrophysiology.

Addition of beta and Cm in *EM_MAT_003 and *EM_MAT_005.

Added Godunov method using MF2 in MPP for EP bidomain.

Addition of *EM_MAT_005 with 2 conductivity tensors for EP bidomain model.

Addition of implicit and first order operator split (+ combination of the 2) in

monodomain method.

Added activation time as a d3plot output as well as an ASCII file

(x,y,z,time) at each node. In d3plot, the activation time is at the

ohm heating power for now.

Added transmembrane potential in d3plot output: it is in

the scalar potential for now.

III. Resistive Spot Welding

Addition of resistive spot welding in 2D (rsw2d).

Addition of contact Joule Heat Rate for contact resistance in rsw2d.

Addition of resistive heating solver in 2D, for rsw in 2D.

Added zero out of em_nodeJHrate in em_zeroEMFieldsOut, so that no more

JHR from the contact resistance is added after EM is switched off.

IV. Eddy current

Added option to use *DEFINE_FUNCTION in LCID for the imposed scalar potential

circuit type in EM_CIRCUIT. Allows users to use their own circuit equation as input.

V. Inductive heating

Added option to define NUMLS, F and A with a Load Curve function of the macro time

if a negative integer value is entered.

VI. Miscellanous EM

Creation of d3p_bemDecomp file if gmv > 0 in *EM_OUTPUT with BEM face domains.

Corrected an MPP issue for the EM solver that could occur in problems where some

solid and shell elements have the same element number.

________________________ Forming Analysis __________

A special form of shell h-adaptivity called “tube adaptivity” can now be invoked

using *DEFINE_BOX_NODES_ADAPTIVE. Here, fission and fusion occurs in shells located

inside a “tube”, that is, a torus-shaped volume, based on the path of a moving tool.

This form of adaptivity can help reduce simulation time for incremental forming or roller hemming.

*ELEMENT_BLANKING:

Fix corner trimming problem of a flat blank, where the corner elements would not

follow the trim line when trimmed.

*CONTROL_FORMING_ONESTEP:

– Improve support to-be-unfolded part as a dynain file, by accepting *ELEMENT_SHELL_THICKNESS,

*INITIAL_STRESS_SHELL,and *INITIAL_STRAIN_SHELL.

– Add *MAT_123 to onestep method.

– Fix friction force calculation error.

– Improvements: some of the executables were not able to use multiple CPU in SMP

before, now it is possible.

*CONTROL_FORMING_TRIMMING, *DEFINE_CURVE_TRIM:

– Fix bug in trimming: some of the history variables were lost during trimming.

– Fix bug: some SPC nodes were mistakenly removed.

– Fix bug in trimming of sandwiched part with multi-layerd core: shells were wrongly

created for every layer of the sandwiched core.

– Improve trimming of solid elements: allow the corner to be trimmed exactly as the trim curve.

*CONTROL_FORMING_TRIMMING, *DEFINE_CURVE_TRIM_3D:

Improve trimming with _3D option: if a vector id is provided (by mistake) with 3D trimming,

the code will set the vector to be zero, as 3D trimming does not require a vector.

*DEFINE_CURVE_TRIM_2D:

Change from *DEFINE_CURVE_TRIM_NEW to *DEFINE_CURVE_TRIM_2D.

*CONTROL_FORMING_REMOVE_ADAPTIVE_CONSTRAINTS:

– Fix segmentation fault.

– Extend to triangular elements, in addition to quadrilateral elements.

*CONTROL_IMPLICIT_FORMING:

– For IOPTION=2, fix a truncation error that prevented completion of the analysis.

– Fix a bug that prevented application in dynamic implicit analysis.

– Fix kinetic energy calculation error.

*DEFINE_FORMING_CLAMP:

– Add error message: “Vector: xx was not defined” in case vector’s direction is defined incorrectly.

– Check constraints for the rigid clamper and free the constraints from the moving clampers.

*DEFINE_PART_FROM_LAYER:

Add *CONTACT_SURFACE_TO_SURFACE between layers generated by this keyword.

*CONTROL_FORMING_AUTOPOSITION_PARAMETER:

– If separation distance cannot be found, for example, when the MPID is not found when

calculating the separation distance, or out of position, or the DIR is not input correctly,

instead of returning a very large number, the value of PREMOVE will be returned.

– Support *DEFINE_COORDINATE_VECTOR.

*CONTROL_FORMING_OUTPUT:

– Enable the variable NOUT not only in punch drawing but also in binder closing.

– Allow output of d3plot according to NOUT without using y1,y2,… or a curve id.

– Fix a bug to prevent excessive intfor output.

*DEFINE_FORMING_BLANKMESH:

Fix X, Y shifting problem (not working) for NPLANE=2 and 3.

*INCLUDE_AUTO_OFFSET:

– Extend to beam and solid elements.

– Fix a beam offset problem when adaptivity is turned on.

– Add a new option _USER. User can now control how much the node and shell element are offset.

In addition, with this option, the offset can be used for sheet blank part. Without this

option, the auto offset can only be used for rigid bodies.

– Extend _USER option to include solid and beam parts.

*CONTROL_FORMING_TIPPING:

Improve this keyword to allow three source coordinates and the corresponding three

target coordinates for the tipping. Use NMOVE=-6 to activate this feature.

*CONTROL_FORMING_UNFLANGING:

Fix a segmentation fault when writing the result file ‘unflanginfo.out’.

*DEFINE_MULTI_DRAWBEADS_IGES:

Fix a duplicate node set issue when SMOOTH contact is used with automatic

draw beads generation from IGES.

*CONTROL_FORMING_PRE_BENDING:

Add a warning message that the keyword must be placed at the end of the input file.

*DEFINE_BOX_DRAWBEAD:

Fix a bug in calcuating the box size.

*CONTROL_FORMING_STONING:

Allow the element set to be defined with *SET_SHELL_GENERAL and *DEFINE_BOX.

*DEFINE_FIBERS, and *CONTROL_FORMING_ONESTEP:

– Add a new keyword (*DEFINE_FIBERS) to define carbon fibers and their related properties

for one-step inverse forming simulations of carbon fiber reinforced composites.

– Output initial flat part, which is re-orienated by aligning node N1 and N2 in x-direction.

– Output element fiber information, including orientation and width.

– When N1 or N2 is zero or undefined, another line of input is required for the

target coordinates for N1 and N2, and the code will find the nearest nodes.

– Outputs:

1st history variable: the angle between two fibers.

2nd history variable: the angle between the first fiber with respect to the element direction.

3rd history variable: the angle between the second fiber with respect to the element direction.

– Up to three major fiber reorientations are allowed.

*CONTROL_FORMING_STRAIN_RATIO_SMOOTH:

Change keyword name from *CONTROL_FORMING_TOLERANCE to *CONTROL_FORMING_STRAIN_RATIO_SMOOTH.

*CONTROL_FORMING_AUTOCHECK:

– Add a new variable IFSHARP. When IFSHARP=0, check the sharp edge and delete the elements;

when IFSHARP=1, ignore sharp edge.

– Check for and fix for triangular elements incorrectly defined with four unique nodes.

*INTERFACE_COMPENSATION_FLANGE:

Added this new keyword to handle flanging die compensation.

*DEFINE_PART_FROM_LAYER:

Add a new keyword to generate multi-layers of shells for a composite structure

(carbon fiber material, for example).

*ELEMENT_LANCING:

Add lancing of multi-layered solid elements.

*CONTROL_FORMING_BESTFIT:

– Add some bestfit statistics in the “messag” file after best fit. The first column

is the percentage of nodes within the range indicated; the second column is the

percentage of nodes within the upper limit of the range indicated.

– Output the maximum gap.

*DEFINE_CURVE_FLD_FROM_TRIAXIAL_LIMIT, and *DEFINE_CURVE_TRIAXIAL_LIMIT_FROM_FLD:

Added these two new keywords.

*INCLUDE_COMPENSATION_TRIM_NODE:

Add a new option which will include a file containing all the nodes near the trimming

line. This file should be generated from *INTERFACE_COMPENSATION_NEW_REFINE_RIGID (bndnd0.tmp).

*INTERFACE_COMPENSATION_3D:

– Add a new option _REFINE_RIGID to automatically identify the nodes near the trimming

curves, so surface compensation later will be smoother.

– Add a new variable TANGENT. TANGENT=1 maintains the boundary tangency from the addendum to the binder.

– Combine rigid refinement along trimming curve into the main compensation in one single run.

– Change keyword *INTERFACE_COMPENSATION_NEW to *INTERFACE_COMPENSATION_3D.

________________________ *FREQUENCY_DOMAIN ___________________

Added logic for some frequency response computations so that the amount

of drilling rotation control is the same as for eigenvalue computations.

*DATABASE_FREQUENCY_ASCII_OPTION:

– Added modal contribution fraction output to NODOUT_SSD and ELOUT_SSD.

– Added option NODFOR_SSD as an option to *DATABASE_FREQUENCY_ASCII.

– Added options NODOUT_PSD and ELOUT_PSD for random vibration analysis.

*DATABASE_FREQUENCY_BINARY_OPTION:

– Added D3ZCF binary database to fringe plot zero-crossing frequencies (with positive

slope) in random vibration analyis.

– Added D3ACC binary database to fringe plot acoustic pressure contribution from

boundary elements in BEM acoustic computation.

*FATIGUE:

– Implemented this keyword to run time domain fatigue analysis based on stress or strain.

– Added new mean stress correction methods: Goodman-tension-only and Gerber-tension-only

to provide conservative analysis for compression mean stress.

– Added an option EN to *MAT_ADD_FATIGUE to define material’s EN curve.

– Improvement to skip fatigue computation if the local strain is less than 1.e-6.

– Improved strain based fatigue analysis when using Maximum Shear Strain and using

Signed Von Mises strain.

– Added restart option RESTRT to fatigue analysis, if the stress/strain time history

has been precomputed.

*FREQUENCY_DOMAIN_ACOUSTIC_BEM:

– Added half space option to dual BEM based on Burton-Miller formulation.

– Implemented incident wave to Kirchhoff method.

– Implemented incident wave to Burton-Miller BEM.

– Implemented incident wave to Rayleigh method.

– Fixed bug in running acoustic analysis with multiple boundary conditions in MPP.

– Enabled running BEM restart (ibemrest=6) based on atv matrix computed previously. SMP only.

– Generating D3ACS database for collocation bem (method=3) and dual collocation bem (method=4) only.

*FREQUENCY_DOMAIN_PATH:

Added option _NOJOBID, so that users can run restart based on the same eigenvector database

for each CASE (otherwise, LS-DYNA will add different prefix to the file name in each

CASE automatically).

*FREQUENCY_DOMAIN_RANDOM_VIBRATION:

– Added the following new load types for random vibration analysis:

VAFLAG = 9 base velocity

10 base displacement

11 enforced acceleration by large mass method

12 enforced velocity by large mass method

13 enforced displacement by large mass method

– Fixed a bug in running PSD interpolation when log-log interpolation is used and

the PSD includes both magnitude and phase delay (for cross PSD).

– Implemented Lalanne method for frequency domain fatigue analysis.

– Added option LCTYP2 to define phase difference in cross psd by degrees and radians.

*FREQUENCY_DOMAIN_RESPONSE_SPECTRUM:

– Changed the rule of dumping nodal displacement results to D3SPCM. Now the state variable

of nodal displacement results is the displacement peak value itself, without adding

original nodal coordinates. LS-PrePost has been updated to accomodate this change.

– Added xyplot file spectrum_curve_print. This file saves the intermediate base acceleration

spectrum, converted from base motion time history (LCTYP=10, 11, 12).

– Added the following new load types for response spectrum analysis:

LCTYP = 5 (base velocity vs natural period)

6 (base acceleration vs natural period)

7 (base displacement vs natural period)

8 (nodal force vs natural period)

9 (pressure vs natural period)

10 (base velocity time history)

11 (base acceleration time history)

12 (base displacement time history)

– For group force computation, now we calculate the group force for each mode first and

then run the mode combination on them. Previously we calculate the group force as

the sum of the nodal force, after the mode combination.

– Added Von Mises stress output for beams for response spectrum analysis.

– Updated response spectrum analysis so that it can work with intermittent eigenvalue analysis.

– Added nodal force and group force output (NODFOR_SPCM) for response spectrum analysis.

*FREQUENCY_DOMAIN_RESPONSE_SPECTRUM_DDAM:

– Implemented DDAM for navy ship shock response analysis.

– Implemented CSM (Closely Spaced Modes) treatment for DDAM.

– Added mcomb=-14 to run DDAM with user defined CSM.

– Added a new parameter EFFMASS, to define a required mininum percentage for total modal mass,

to decide the modes to be used in DDAM analysis. The default value is 80 (80%).

– Added a parameter UNIT, to define the unit system in the input deck, as the NAVSEA constants

are only valid with the BIN unit system.

*FREQUENCY_DOMAIN_SSD:

– Implemented mean stress correction for SSD fatigue analysis.

– Implemented option restmd=2 to restart with old scratch file modeshp to save time.

– Implemented an option _FRF to *FREQUENCY_DOMAIN_SSD, to provide FRF results in SSD.

– Added option _MODAL_CONTRIBUTION to output modal contribution fraction for nodes and elements.

– Enabled combination of modal damping and local damping in SSD computation.

– Added the following new load types with rotational degree-of-freedom.

VAD = 9 (base angular velocity)

10 (base angular acceleration)

11 (base angular displacement)

________________________ ICFD (Incompressible Fluid Solver) ______________

New ICFD features and major modifications:

– Major rework of the boundary layer mesh generation capabilities. See MESH_BL keyword.

– Major rework on the wave generation capabilities. Added 2D and 3D solitary waves as

well as a irregular wave model (JONSWAP spectra). See *ICFD_BOUNDARY_FSWAVE keyword.

– Added an option so that pmin and pmax in MESH_SIZE_SHAPE can be defined using *ICFD_DEFINE_POINT.

The big advantage is that *ICFD_DEFINE_POINT can move and therefore *MESH_SIZE_SHAPE as well.

Also added new Shape name : SPOL as well as birth and death times.

– Added keyword to define a volumetric heat source. See *ICFD_DEFINE_HEATSOURCE.

– Added keyword which allows the user to define an initial plane for levelset rather than building

the initial interface mesh. See *ICFD_INITIAL_LEVELSET.

– Added keyword to control gap size in embedshell cases. See *ICFD_CONTROL_EMBEDSHELL.

Small feature additions in ICFD and modifications to existing keywords:

– Output frequency of d3plot in steady state in now controlled by sixth flag of *ICFD_CONTROL_OUTPUT.

– Added output frequency for *ICFD_DATABASE_TEMP.

– *ICFD_DEFINE_POINT : can now be made to follow a surface part’s displacements.

– Allowing *DEFINE_FUNCTION to be used for R and LCID in *ICFD_DEFINE_NONINERTIAL.

– *ICFD_CONTROL_GENERAL : potential flow solver can now be used in transient analysis

(which can for example be useful in cases like conjugate heat transfer).

– *ICFD_MAT : added the option to scale the surface tension by using a load curve or a *DEFINE_FUNCTION.

Bug fixes in ICFD:

– Fix temperature SUPG stabilizing parameter for Conjugate Heat Transfer problem.

– Fix the viscosity as a function of temperature when using Non-Newtonian fluids

with NNID=6,7,8 in Free-Surface problems.

– Fix the surface tension force term.

– Fix issue in multiphase algorithm. Stability and accuracy greatly improved.

– Improved stability of k-epsilon model in steady state solver.

Minor ICFD improvements:

– Change the nodal assembly by an element integration and assembly.

in anisotropic porous media solver. This way, forces at porous media

interfaces are better described for coarse meshes and thin porous

media domains.

-Split the mesh statistics in icfd_mstats.xxx.dat into bulk mesh and boundary layer.

– Added ‘wetness’ variable for free surface cases that shows how much a surface has touched the water.

– Support of icfd_timeiter.dat for the steady state solver.

– Added timer for potential flow solver.

– Added a spatial smoothing for the surface shear stress calculation.

– Added ICFD endtime in d3hsp initial keyword reading.

– Accelerated heat transfer calculation.

– Added a small warning that ICFD does not scale in SMP with ncpu higher than 1.

– Change in unreference node detection criteria. Before, it was stopping with an error message,

now it proceeds with a warning.

– Added warning when porous media model or non newt model not detected.

-Added avg pre and avg flux to ICFD_DATABASE_FLUX output.

________________________ Implicit (Mechanical) Solver _______

*CONTROL_IMPLICIT_MODAL_DYNAMIC:

– Support output to elout for modal dynamic analysis.

– Make performance enhancements for transient modal analysis including the implicit Newmark scheme

for time integration and a node set for loads in *CONTROL_IMPLICIT_MODAL_DYNAMIC.

When using a direct solver for implicit (LSOLVR = 2 or 6 in *CONTROL_IMPLICIT_SOLVER),

the system of linear equations is reordered (permuted) to reduce the solution cost.

Up to and including version R10, two options were available: MMD (Multiple Minimum Degree) and

METIS (external package from University of Minnesota). These two options are serial algorithms,

and they might run out of memory or consume a large fraction of total run time for very large models.

As of version R11, a parallel, distributed-memory algorithm, LS-GPart, is introduced.

It scales in both memory and time and should only be attempted for very large MPP implicit models

and with the guidance of implicit support staff at LSTC (support@lstc.com).

LS-GPart can be used by setting variable ORDER to 4 in *CONTROL_IMPLICIT_SOLVER).

A new keyword *CONTROL_IMPLICIT_ORDERING was also introduced to fine-tune ordering options.

Correct a number of minor issues with memory access for implicit.

Enhance implicit handling of nodal inertia for special cases.

Fix divide by zero in power iteration for buckling problems with inertia relief.

Enhancements for matrix dumping left out the special case of matrix dumping

for intermittent eigenvalue problems which is now corrected.

Adjust output to d3hsp for implicit linear equation solver options to

match keyword manual.

Correct the MPP implementation for the new stiffness control on implicit rotational dynamics.

Adjust shift logic for lanczos eigensolver for a special case.

Enhance implicit treatment of sense switch sw1 to avoid issues in SMP.

Apply correction for a problem that computed way too many eigenmodes in one iteration

of the MPP eigensolver.

Add the new feature for the specification of stiffness types for

*CONTROL_IMPLICIT_ROTATIONAL_DYNAMICS.

Lower the implicit dynamic memory greed factor from 0.85 to 0.80.

Put end-of-file tag on d3eigv after writing stresses for MCMS eigensolver.

Normalize MCMS computed eigenvectors to have unit norm.

Correct the dumping of matrices from implicit when MTXDMP > 1.

Correct a misalignment of statements in flxinit causing SMP to fail with

*PART_MODES and the use of the PARTM feature from *CONTROL_RIGID.

Implement handling of failure of *CONSTRAINED_TIE-BREAK for implicit.

Required saving of the failure flag to use when constraint matrix structure has

to be the same as the last analyze phase.

Fix long standing potential memory clobber for single precision SMP implicit.

(Nevertheless, single precision is not recommended for implicit.)

Improve implicit logic for determining which DOFs are active for 2D

problems in MPP.

Enhance the modal stress scaling to be more responsive to model features to make

the computation more robust.

Enhance implicit key point logic during dynamic relaxation phase. We

were using the incorrect end time which led to a zero time step.

Add error test for when dynamic relaxation is using implicit (idrflg=5 or 6)

but DRTERM is not specified.

Correct the MPP implementation of *PART_MODES so that the part can now be

distributed across processes.

Enable implicit to collect resultant forces for SPC constraints in

local coordinates.

Fix *CONTROL_IMPLICIT_MODES to correctly build superelements in MPP.

For implicit MPP, correct tagging of the end of each d3eigv* file.

Reduce memory requirements for MPP Lanczos.

Enhance implicit to recognize superelement mass in the mass matrix multiplication.

Enhance *CONTROL_IMPLICIT_MODES to be able to create a superelement for a

model that was already using a superelement.

Enhance the specification of IMFLAG<0 for *CONTROL_IMPLICIT_GENERAL.

The old approach only allowed toggling between 0 and 1 using a curve.

This was extended to allow ordinate values of 0, 1, 4, or 5 in the curve

controlling implicit/explicit switching.

Enhance processing of rotational inertias for implicit, especially

discrete elements and rigid body inertias.

Add additional implicit debugging by checking the ends of beam

elements and what they are or are not connected to.

Reset more arrays to get the nonlinear elements to work correctly

for implicit linear multi-step (NSOLVR = -1).

If two independent nodes for *CONSTRAINED_INTERPOLATION have the

same coordinates then a divide by zero could happen. That has been corrected.

Add INTERFACE_SPRINGBACK to the cases where implicit collects and processes

damping terms instead of suppressing them as is the case for implicit statics.

Update implicit’s collection of damping terms for discrete elements

to account for user specified coordinate system and the case of no

second node.

Patch up reporting of bad pivots in MPP.